Bevel Gears India provides solutions for users of ground spiral bevels, spiral bevels, spiral, straight, zerol, angular and hypoid gears. Contact us with your requirements.

Products

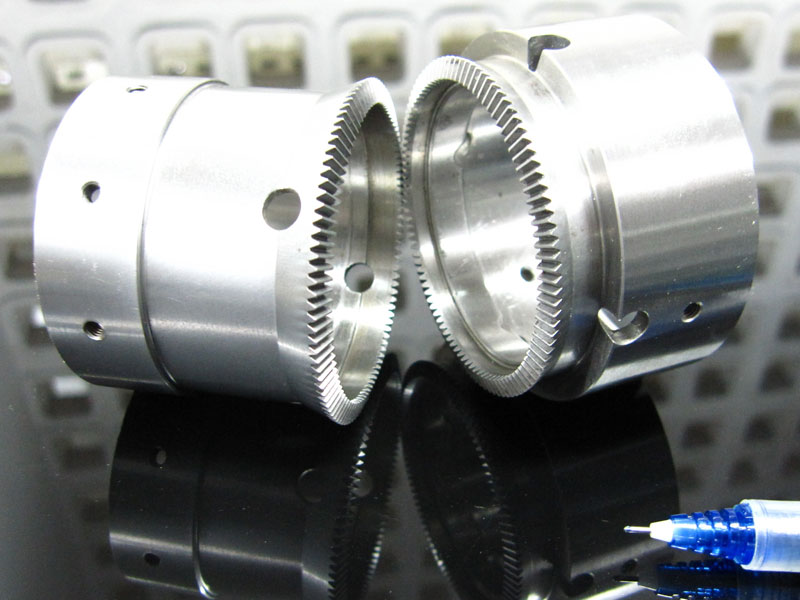

Ground Spiral Bevel Gear

- Range: 25 – 800 mm (1”-32”)

- Ground spiral bevel gears are used for demanding applications with the highest accuracies

- Benefits include lower noise, higher rpm capabilities, improved surface finish, and lower vibrations

Hard Cut Spiral Bevel Gear

- Range: 75 – 1200 mm (3”- 48”)

- High power capacity and excellent surface finishes are offered with hard cut spiral bevel gears

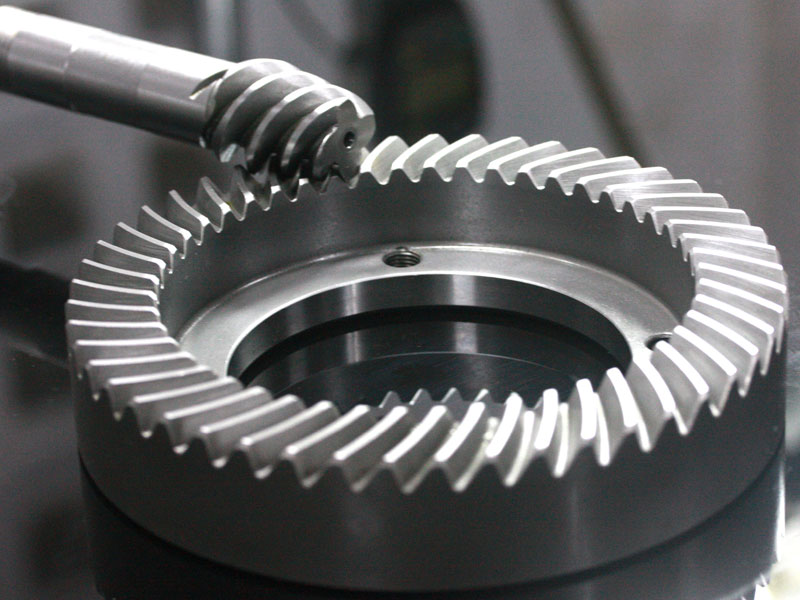

Lapped Spiral Bevel Gear

- Range: 5 – 1600 mm (0.2”- 63”)

- Up to 1600 mm with optimized contact patterns

- High contact ratio with multiple teeth in mesh and localized contact patterns for smooth running

Ground Straight Bevel Gear

- This is a unique offering that we provide

- Master straight bevel gears

- Higher accuracies, reduced distortion and improved running conditions

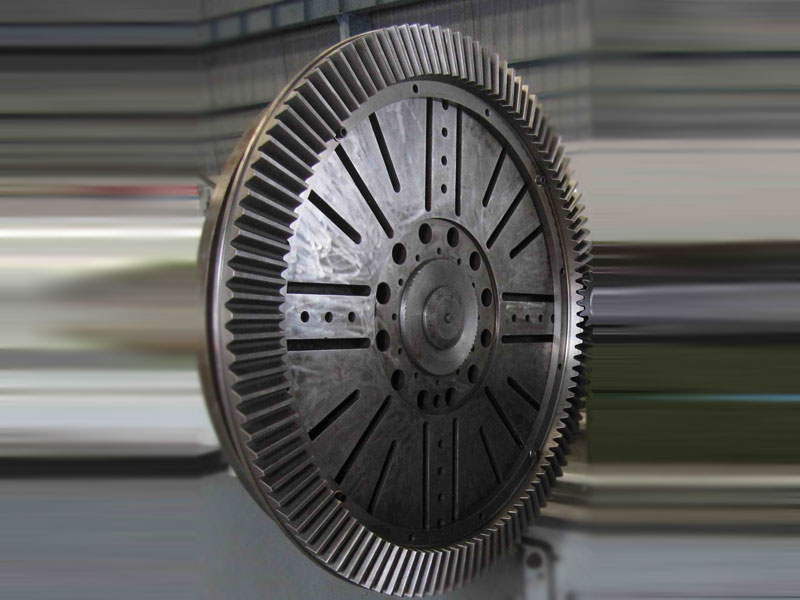

Straight Bevel Gear

- Range: 5 – 1800 mm (0.2”-72”)

- Localized contact patterns assist in smoother running straight bevel gears

Hypoid Gear

- Hypoid gears are similar to spiral bevel gears except that they operate on non-intersecting axes

- We can manufacture 4-tooth hypoid pinions which allow very high single stage reductions

- High reduction Hypoids (HRH®) for ratios upto 1:110 available

Angular Bevel Gear

- Type: Straight & Spiral

- Bevel gears above and below 90 degree shaft angles can be manufactured to your specifications

Zerol Gear

- Zerol bevel gears are similar to spiral bevel gears except they normally have zero degree spiral angles

- Up to 1270 mm (50”) in diameter, depending upon configuration

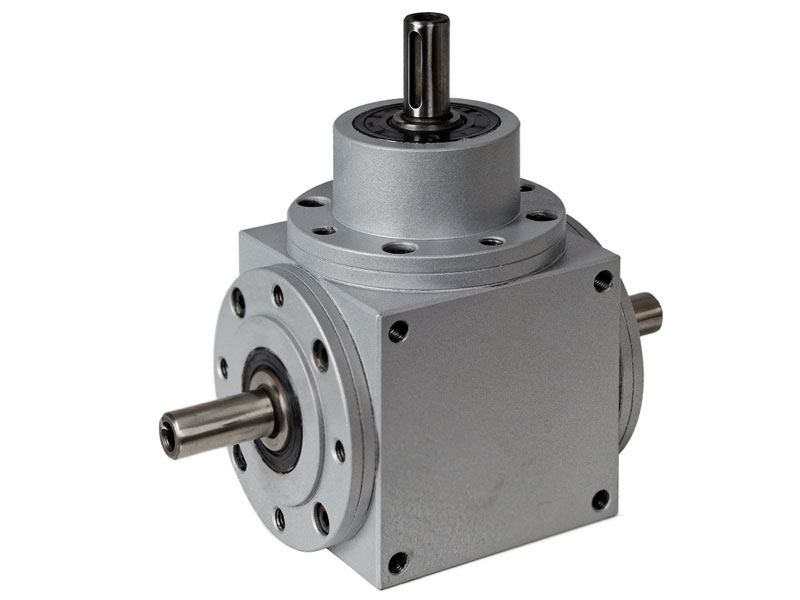

Cube Gearbox

- Industrial Bevel Gear Boxes 2 way, 3 Way & Hollow Shaft

- Low backlash cube gear box for industrial applications

- Housing Raw Material options:

- Steel

- Cast iron

- Stainless steel

- We use heat treated & lapped spiral Bevel Gears

- Customized Cube Boxes Available

- Ground Spiral Bevel Boxes are also available for high precision applications

- Drop-in gear sets for branded gearboxes available

Gearboxes Specification

| SIZE | KL-65 | KL-75 | KL-90 | KL-100 | KL-120 | KL-160 | KL-200 |

| 1:1TO2:1 | 1:1TO2:1 | 1:1TO2:1 | 1:1TO2:1 | 1:1TO2:1 | 1:1TO2:1 | 1:1TO2:1 | |

| A | 25 | 30 | 35 | 38 | 45 | 60 | 80 |

| B | - | 2 | 2 | 3 | 3 | 3 | 3 |

| C | 43.5 | 54 | 55 | 62 | 75 | 98 | 120 |

| D1 | 12 | 16 | 18 | 20 | 26 | 36 | 42 |

| D2 | 12 | 16 | 18 | 20 | 26 | 36 | 42 |

| D | 83 | 85 | 95 | 110 | 122 | 160 | 203 |

| E | 11 | 11 | 10 | 13 | 15 | 18 | 20 |

| F | 65 | 75 | 90 | 100 | 120 | 160 | 200 |

| G | 22.5 | 27.5 | 35 | 40 | 50 | 60 | 80 |

| H | 75 | 80 | 85 | 110 | 115 | 150 | 190 |

| I | 100 | 110 | 122 | 150 | 162 | 212 | 262 |

| M | M5 | M5 | M8 | M8 | M10 | M12 | M12 |

| W | 4*4*20 | 5*5*22 | 6*6*28 | 6*6*30 | 8*8*35 | 10*10*45 | 12*12*65 |

| GEAR BOX DATA | KL-65 | KL-75 | KL-90 | KL-100 | KL-120 | KL-160 | KL-200 |

| INPUT POWER (kw) | 1.0 | 1.5 | 2.2 | 3.0 | 5.0 | 15.0 | 20.2 |

| INPUT RMP MIN | 1000 | 1000 | 500 | 500 | 500 | 500 | 500 |

| INPUT RMP MAX | 3000 | 3000 | 1440 | 1400 | 1400 | 1440 | 1400 |

| OUTPUT TORQUE MAX | 10Nm | 14Nm | 42Nm | 57Nm | 96Nm | 287Nm | 382Nm |

| OUTPUT TORQUE MIN | 3Nm | 5Nm | 15Nm | 20Nm | 33Nm | 99Nm | 133Nm |

| GEAR BOX DATA | KL-65 | KL-75 | KL-90 | KL-100 | KL-120 | KL-160 | KL-200 |

| INPUT POWER (kw) | 1.0 | 1.5 | 2.2 | 3.0 | 5.0 | 15.0 | 20.2 |

| INPUT RMP MIN | 1000 | 1000 | 500 | 500 | 500 | 500 | 500 |

| INPUT RMP MAX | 3000 | 3000 | 1440 | 1400 | 1400 | 1440 | 1400 |

| OUTPUT TORQUE MAX | 19Nm | 29Nm | 84Nm | 115Nm | 191Nm | 533Nm | 364Nm |

| OUTPUT TORQUE MIN | 6Nm | 10Nm | 29Nm | 40Nm | 66Nm | 199Nm | 265Nm |

Contact now